-

aditya@xsun.in -

View Mobile Number - Send SMS

- Send Email

Metalworking Fluids

Leading Manufacturers, Exporters, Wholesaler, Retailer and Trader of EDM Oil, Grinding Fluids and Machining Fluids from Delhi.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

Preferred Buyer From

| Location | Anywhere in India |

Make a good impression on potential customers by eliminating the smoky, smelly, kerosene based edm oil is an easy way to clean up your image, and improve your bottom line.

Sun chem brand edm oils are multipurpose dielectric fluids for use in all discharge machines especially for roughing, finishing and superfinishing work. These are formulated with high-purity fluid designed for maximum machine productivity and operator comfort when used in electrical-discharge machining. The chemistry of these products provides correct balance of viscosity, volatility, oxidation stability, heat transfer characteristics and low toxicity. They are highly refined, narrow-cut, low-viscosity fluids and function as an insulator between tool and workpiece.

Do you know how to choose edm dielectric oil

- If you are old enough to remember the days of injection mold making with disgusting edm dielectric oil you qualify to to appreciate how clean, odorless (almost) and safe the fluids found in sinker edm’s are these days.

- Work floor used to smell like a diesel at the end of the with all those disgusting fumes that soaked into the lungs. After all, the odors we smell are actually tiny particles of matter that get picked up by our noses.

- Not only will the use of up-to-date edm oil enhance your profits, it will also boost morale of the edm department and not be offensive to visiting customers.

Advantages of quality edm dielectric oil

- Faster machining speeds-the newer oils are highly refined and purified to be more efficient. They are engineered to burn cleaner, thus producing a finer finish more quickly.

- Less smoke-the smoke produced from high amperage burns can produce quite a bit of toxic smoke, which must be vented to the outside. Even then, what becomes of the smoke?

- Longer fluid life-because they enable electrical discharge machining to be more efficient, the heat and sludge does not degrade the oil as quickly. This can mean quite a savings in material and time.

- Easy on the skin-many operators complain of skin irritation from the old kerosene based fluids. The new synthetic edm oils are much easier on the skin.

- Does not evaporate-your oil will last longer, and your shop will not smell like a diesel engine repair shop.

- Environmentally friendly-because the new edm oils are synthetic they are much easier to dispose of and have less impact on the environment.

You only get once chance to make a good first impression

Choosing the correct edm oil can make a substantial difference in the overall performance of your edm department. Buying good edm supplies makes sense any way you look at it.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Application | For All Grinding Operations |

| Technology | Formulations based on American / European standard |

| Packaging Size (Litres) | 25 ltr / 210 ltr |

| USP | Quick removal of swarfs, Clean grinding wheels , Economical |

| Advantage | No rusting , Excellent Surface finish |

Preferred Buyer From

| Location | Anywhere in India |

Grinding: We understand that grinding fluids are crucial in the grinding process. Not only are they needed to reduce friction, but also for their ability to extract heat from the work zone and maximize material removal. This is why are grinding fluids are formulated with advanced polymers, corrosion inhibitors and powerful detergents that result in superior quality surface finishes. Our technology is developed for use in OD/ID, Blanchard, surface, internal, form and cylindrical grinding applications. All of the products are compatible with diamond, CBN, vitrified and resin-bond wheels. The products are formulated from high-purity, natural petroleum and synthetic base stocks. They are job specific and are available in a range of viscosities that will complement any filter system.

A. Mineral

These fluids are low-viscosity, low-smoke grinding oils using special additives for effective grinding of high nickel alloys, tool steel alloys and carbide. These products provide excellent heat transfer coupled with high lubricity that help eliminate tool micro-structure damage and surface discoloration. These products are non-toxic and non-irritating to machine operators. It is not corrosive to steel, carbide or non-ferrous alloys. High lubricity, excellent wetting and extreme pressure properties help extend grinding wheel life, maintain wheel form and minimize burning.

B. Synthetic

Our synthetic fluids are very low-viscosity, low-smoke synthetic grinding oils for tool steel and carbide respectively. These products are blends of special additives in synthetic oil for increased lubricity and burn-free performance at elevated temperatures. Both products are formulated with an additive package that will not be stripped by diatomaceous earth filter systems or quickly depleted during use.

C. Semi-Synthetic

These fluids are blends of synthetic hydrocarbon, synthetic ester and highly refined mineral oil. These are low-viscosity, low-smoke grinding oils that exhibit high lubricity at a reduced viscosity to maximize heat transfer for excellent grinding performance.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

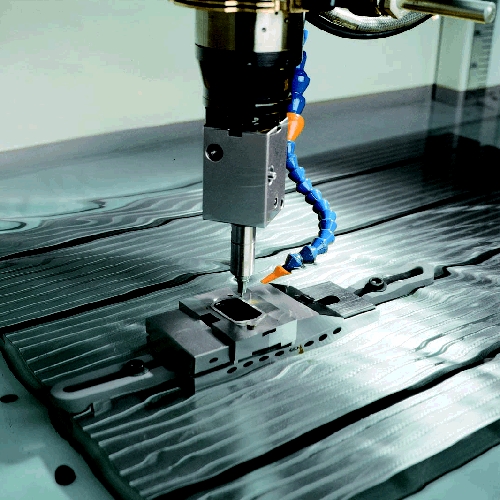

| Application | For Most Advanced CNC / Lathe Machines |

| Technology | Formulations based on American / European standard |

| Packaging Size (Litres) | 25 ltr / 210 ltr |

| USP | Highly stable emulsions, Low top up rates, Huge savings |

| Advantage | Tool life increase , Better product finish |

Preferred Buyer From

| Location | Anywhere in India |

Microcool : Cooling lubricants for metalworking must always be effective, but also economical and free from ingredients that are harmful to health and the environment. They must provide cooling and lubrication, as well as flush chips away from the cutting zone, provide corrosion protection, keep foaming under control and be highly stable. Our fluids are designed with today’s most advanced additives to properly balance all of these functions in a variety of operations involving a myriad of substrates.

A. Synthetic

Our Synthetic Machining fluids provide thermal and oxidation stability, rapid heat dissipation from tooling and work pieces, along with minimizing oil misting and smoking. Specially formulated with pure technology, advanced polymers and powerful detergents this line exceeds the demands of today’s machining industry by achieving optimal high-quality surface finishes. They are designed with enhanced wetting agents which will lead to low coolant carry-out and reduced consumption, clean running, low foam and their transparency allows the operators to see the parts during the manufacturing process.

Benefits

- Excellent tool life cuts downtime and tooling costs

- Increased feeds and speeds

- Bacteria-resistant

- Oil rejecting properties

- Longer sump life, reduces waste streams

- Non- Staining

- Low residue

- Fine Settling

- Foam Control, designed for both low and high pressure systems

- Stability for both hard and soft water

- Corrosion Protection

Our wide range of synthetic fluids can be used on Ferrous, Non-Ferrous and Specialty Metals taking into account machining and metal compatibility.

Light Duty – general purpose machining

Light-Moderate Duty – facing, milling, sawing and general machining

Moderate Duty – turning, grooving, milling, tapping, and drilling

Heavy Duty – broaching, deep boring, drilling, reaming, roll threading and tapping

B. Semi-Synthetic

What sets us apart in today’s global market with our Semi-Synthetic fluid line? The diversity among this series that was designed for plant operations that demand exceptional machining finishes, extended tool life while having operator acceptance. These products are water extendable and scientifically formulated to provide an outstanding balance of extreme pressure characteristics, boundary lubrication, low foaming and cooling properties in all phases.

Benefits

- Improved tool life

- Increase feed and speeds

- Clean Operating – Residue Free

- Longer sump life

- Excellent wetting characteristics

- Microbiological protection

- Hard/Soft water stability

- Excellent surface finishes

- Excellent detergency

- Defoaming properties (low and high pressure)

- Corrosion protection

Our wide range of semi-synthetic fluids can be used on Ferrous, Non-Ferrous and Specialty Metals taking into account machining and metal compatibility.

Light Duty – band saw applications

Light-Moderate Duty – general machining, grinding, sawing, drilling and facing

Moderate Duty – general machining, facing, milling, sawing, and turning

Moderate-Heavy Duty – facing, milling, sawing and turning

Heavy Duty – boring, facing, reaming, tapping, gun drilling, roll forming and broaching

C. Soluble

Our soluble oil line is highly engineered to provide superior lubrication even in the most demanding metalworking applications. They are formulated with premium base oils, unique emulsion packages, effective bio-resistant components along with extreme pressure and lubricity additives to provide maximum tool life that have high quality finishes.